![]() AlNiCo Magnets Introduction

AlNiCo Magnets Introduction

01. AlNiCo Magnets Profile

AlNiCo permanent magnets: a metal alloy composed of aluminum, nickel, cobalt, iron and other trace element composition. AlNiCo permanent magnets have two different production processes: casting and sintering. AlNiCo magnets can be made into different sizes and shapes by casting process. Compared to casting process, Sintered magnets’ size is smaller, but its dimension accuracy is better than the rough casting magnets. Sintered magnets’s magnetic performance is slightly lower than casting magnets, but its processability is better. AlNiCo magnets offer the best temperature characteristics among all the magnet materials. AlNiCo magnets can be used for continuous duty applications where the temperature up to 930°F (500°C). AlNiCo magnets exhibit a high degree of corrosion resistance and are typically employed in the applications unsuitable for coatings or plating surface treatment.

The lower coercive force of AlNiCo makes magnetizing a simple matter in most cases. In order to optimize the performance of AlNiCo magnets, it is advisable to magnetize the magnet after assembly with other circuit components. AlNiCo Magnets are very strong and brittle, requiring appropriate handling and packing to ensure safety and prevent damage.

Typical Applications for AlNiCo magnets:

Widely used in the applications such as instruments and meters which require very stable temperature properties.

Electronic ignition systems, watt bour meters, volt-amp meters, medical instruments, industrial motors, magnetic reed switches, generators, hand tools, vending machines.

02. AlNiCo Magnets Production Process

03. AlNiCo Magnets Performance Datasheet

-

Cast AlNiCo Magnets

| Grade | Remanence Br | Coercive Force Hcb | Max. Energy Product (BH)max | Curie Temp. Tc. | Max Working Temp. Tw. | Temp. Coefficient of Br T.C.α (Br) | MMPA Equivalent | IEC Equivalent | Germany Standard | |||

| mT | Gs | kA/m | Oe | kJ/m3 | MGOe | [°C] | [°C] | [%°C] | ||||

| *LN9 | 690 | 6,900 | 37 | 470 | 9.0 | 1.13 | 760 | 500 | -0.03 | AlNiCo3 | AlNiCo9/4 | AlNiCo120 |

| *LN10 | 600 | 6,000 | 40 | 500 | 10.0 | 1.25 | 760 | 500 | -0.03 | |||

| *LNG12 | 720 | 7,200 | 44 | 550 | 12.0 | 1.50 | 810 | 500 | -0.03 | AlNiCo2 | AlNiCo12/6 | AlNiCo160 |

| *LNG13 | 700 | 7,000 | 48 | 600 | 13.0 | 1.63 | 810 | 500 | -0.03 | |||

| LNG16 | 800 | 8,000 | 53 | 660 | 16.0 | 2.00 | 850 | 500 | -0.02 | AlNiCo4 | / | / |

| LNG18 | 1,050 | 10,500 | 48 | 600 | 30.0 | 3.75 | 850 | 500 | -0.02 | |||

| LNG32 | 1,180 | 11,800 | 44 | 550 | 32.0 | 4.00 | 890 | 500 | -0.02 | AlNiCo5C | / | AlNiCo500 |

| LNG34 | 1,180 | 11,800 | 44 | 550 | 34.0 | 4.25 | 890 | 500 | -0.02 | |||

| LNG37 | 1,200 | 12,000 | 48 | 600 | 37.0 | 4.65 | 890 | 500 | -0.02 | AlNiCo5 | AlNiCo37/5 | AlNiCo500 |

| LNG40 | 1,250 | 12,500 | 48 | 600 | 40.0 | 5.00 | 890 | 500 | -0.02 | / | ||

| LNG44 | 1,250 | 12,500 | 52 | 650 | 44.0 | 5.50 | 890 | 500 | -0.02 | AlNiCo44/5 | ||

| LNG48 | 1,250 | 12,500 | 52 | 650 | 48.0 | 6.00 | 890 | 500 | -0.02 | AlNiCo5DG | AlNiCo52/6 | AlNiCo600GD |

| LNG52 | 1,300 | 13,000 | 56 | 700 | 52.0 | 6.50 | 890 | 500 | -0.02 | |||

| LNG60 | 1,350 | 13,500 | 56 | 700 | 60.0 | 7.50 | 890 | 500 | -0.02 | AlNiCo5~7 | / | AlNiCo700 |

| LNGT28 | 1,050 | 10,500 | 56 | 700 | 28.0 | 3.50 | 860 | 500 | -0.02 | AlNiCo6 | AlNiCo26/6 | AlNiCo400 |

| *LNGT18 | 580 | 5,800 | 90 | 1,130 | 18.0 | 2.20 | 860 | 500 | -0.03 | AlNiCo7 | AlNiCo17/9 | AlNiCo260 |

| LNGT32 | 800 | 8,000 | 100 | 1,250 | 32.0 | 4.25 | 860 | 500 | -0.03 | AlNiCo8 | / | AlNiCo350 |

| LNGT34 | 800 | 8,000 | 104 | 1,300 | 34.0 | 4.25 | 860 | 500 | -0.03 | |||

| LNGT38 | 820 | 8,200 | 110 | 1,380 | 38.0 | 4.75 | 860 | 500 | -0.03 | AlNiCo38/11 | AlNiCo450 | |

| LNGT44 | 880 | 8,800 | 120 | 1,500 | 44.0 | 5.50 | 860 | 500 | -0.03 | / | ||

| LNGT48 | 900 | 9,000 | 120 | 1,500 | 48.0 | 6.00 | 860 | 500 | -0.03 | |||

| LNGT60 | 900 | 9,000 | 110 | 1,380 | 60.0 | 7.50 | 860 | 500 | -0.03 | AlNiCo9 | AlNiCo60/11 | / |

| LNGT72 | 1,050 | 1,050 | 112 | 1,410 | 72.0 | 9.00 | 860 | 500 | -0.03 | / | ||

| LNGT82 | 1,100 | 11,000 | 120 | 1,500 | 82.0 | 10.25 | 860 | 500 | -0.03 | |||

| LNGT88 | 1,100 | 11,000 | 120 | 1,500 | 88.0 | 11.00 | 860 | 500 | -0.03 | |||

| LNGT92 | 1,120 | 11,200 | 120 | 1,500 | 92.0 | 11.50 | 860 | 500 | -0.03 | |||

| LNGT36J | 700 | 7,000 | 140 | 1,750 | 36.0 | 4.50 | 860 | 500 | -0.03 | AlNiCo8HC | AlNiCo36/15 | AlNiCo450 |

Note: “*” prior to the grade means isotropic and otherwise anisotropic.

-

Sintered AlNiCo Magnets

| Grade | Remanence Br | Coercive Force Hcb | Max Energy Product (BH)max | Temp. Coefficient of Br T.C.α (Br) | Temp. Coefficient of Hcj T.C.β(HcJ) | Curie Temp. | Max Working Temp. | MMPA Equivalent | IEC Equivalent | |||

| mT | Gs | kA/m | Oe | kJ/m³ | MGOe | %/°C | %/°C | ℃ | ℃ | |||

| *FLN8 | 500 | 5,000 | 40 | 500 | 9 | 1.13 | -0.02 | -0.03 | 760 | 450 | AlNiCo3 | AlNiCo9/3 |

| *FLNG12 | 700 | 7,000 | 48 | 600 | 12.4 | 1.55 | -0.02 | -0.03 | 810 | 450 | AlNiCo2 | AlNiCo12/6 |

| *FLNGT18 | 600 | 6,000 | 90 | 1130 | 18 | 2.2 | -0.02 | -0.03 | 860 | 450 | AlNiCo3 | AlNiCo17/9 |

| FLNG34 | 1,200 | 12,000 | 48 | 600 | 34 | 4.25 | -0.02 | -0.03 | 890 | 450 | AlNiCo5 | AlNiCo37/5 |

| FLNG37 | 1,250 | 12,500 | 48 | 600 | 37 | 4.63 | -0.02 | -0.03 | 890 | 450 | ||

| FLNGT28 | 1,050 | 10,500 | 60 | 600 | 28 | 3.5 | -0.02 | -0.03 | 850 | 450 | AlNiCo6 | AlNiCo37/5 |

| FLNGT38 | 800 | 8,000 | 120 | 1,500 | 38 | 4.75 | -0.02 | -0.03 | 850 | 450 | AlNiCo8 | AlNiCo36/6 |

| FLNGT42 | 880 | 8,800 | 120 | 1,500 | 42 | 5.25 | -0.02 | -0.03 | 820 | 450 | AlNiCo38/11 | |

| FLNGT33J | 700 | 7,000 | 140 | 1,750 | 33 | 4.13 | -0.02 | -0.03 | 850 | 450 | AlNiCo8HC | AlNiCo36/15 |

Note: “*” prior to the grade means isotropic and otherwise anisotropic.

04. SI and CGS Unit Conversion for Magnetism Quantity

| Quantity | Symbol | SI Unit | CGS Unit | Unit Conversion |

| Remanence | Br | T | Gs | 1T=10kGs |

| Coercive Force | Hcb | kA/m | Oe | 1kA/m=4πOe≈12.57Oe |

| Intrinsic Coercivity | Hcj, iHc | kA/m | Oe | 1kA/m=4πOe≈12.57Oe |

| Max. Energy Product | BHmax | kJ/m3 | MGOe | 1kJ/m3=4π/102MGOe≈0.126MGOe |

| Magnetic Flux | Φ | Wb,Vs | Mx | 1Wb=1Vs=108Mx |

| Magnetization Intensity | M | T | Gs | 1T=10kGs |

| Magnetic Field Intensity | H | kA/m | Oe | 1kA/m=4πOe≈12.57Oe |

| Magnetic Induction Intensity | B | T | Gs | 1T=10kGs |

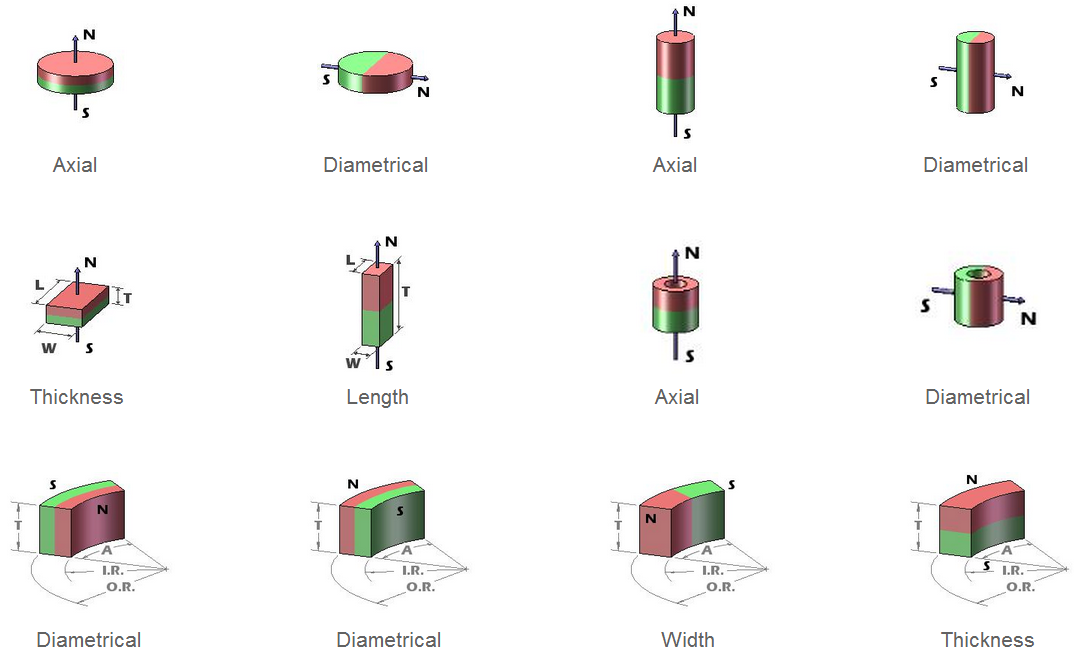

05. AlNiCo Magnets Magnetization Directions

06. Physical Properties of Cast Alnico Magnets

| Curie Temperature | 760-890℃ |

| Max.Operating Temperature | 450-550℃ |

| Resistivity | (47-54)×10-6Ω.cm |

| Vickers Hardness | 520-630Hv |

| Density | 6.9-7.3g/cm³ |

| Relative Recoil Permeability | 1.7-4.7μrec |

| Saturation Field Strength | 2.7-6.3kOe/215-500kA/m |

| Temp. Coefficient of Br | -0.025~-0.03%/℃ |

| Temp. Coefficient of Hcj | +0.01~0.03%/℃ |

07. Permanent Magnets Comparison

| Permanent Magnets | (BH)max (MGOe) | Curie Temperature (°C) | Max. Working Temp. (℃) | Anti-corrosion | Machinability |

|---|---|---|---|---|---|

| Sintered NdFeB Magnets | 27-52 | 310-370 | 80-230 | Bad | Normal |

| AlNiCo Magnets | 1.1-11.5 | 890 | 500 | Good | Fair |

| SmCo5 | 14-25 | 750 | 250 | Good | Normal |

| Sm2Co17 | 22-32 | 800-840 | 350 | Good | Normal |

| Ferrite Magnets | 0.8-5.3 | 450 | 250 | Good | Normal |

| Bonded NdFeB Magnets | 3-12 | 350 | 160 | Good | Good |

08. AlNiCo Magnets Shipping Methods

(TNT, DHL, FedEx, UPS, etc), Air, Sea.

a: If the weight is under 40kgs, we recommend to send it in shielding boxes by Express.

b: If the weight is between 40-100kgs, it can be sent by Express or Air.

c: If the weight is over 100kgs, we recommend to ship them by Sea.

For more details about AlNiCo magnets, please send message to us or email to sales@sinnyuan.com. We will reply to you as early as possible.